PVDF Outdoor Laminated Metal Series

PVDF Laminated metal, high-end solution for exterior wall fences, building materials and clean room

Exterior laminated metal, PVDF laminated metal

The LamiXteel EX25 has a 25-year design standard background and it is made by the Japan's fluorocarbon film. It has excellent chemical and weather resistance and it can replace stainless steel and magnesium aluminum manganese alloy blanks.

Product Description

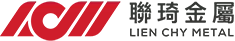

Generally, the PVDF fluorocarbon paint steel has a fluorocarbon coating of about 25 um, and the coating generally contains 70-80% of fluorocarbon resin.

The thickness of the LamiXteel EX25 is 40um fluorocarbon resin which provides excellent UV resistance. The physical properties and chemical specifications far exceeding the general fluorocarbon baking varnish provide excellent protection and durability. Substrate can be selected from EG, GI, GL, AL or other metal materials.

Please scroll down for more PVDF product colors, specifications and testing reports, if you have specific requirements, leaving your message to us on Contact us.

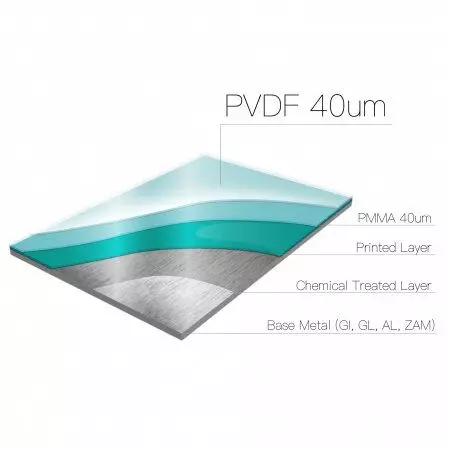

Color Sheet

Test Results

| Item | Test Method | Test Result |

|---|---|---|

| Film hardness | According to the provisions of GB/T 6739-2006. The HB pencil has a load of 500g at a 45° angle and smoothly pushes forward at least 7mm at a speed of 0.5mm/s to 1.0mm/s. | No scratch on the surface of the film |

| Adhesion | The cross-cut method shall be carried out in accordance with the provisions of GB/T 9286, and the circle-cutting method shall be carried out in accordance with the provisions of GB/T 1720. | No lifting, peeling, cracking, etc.; level 0 |

| Salt tolerance | The salt solution is prepared by using sodium chloride (chemically purer) and distilled water at a concentration of 5±0.1% by weight; the pH is between 6.5 and 7.2 (35 ° C); and the substrate standard is hot-dip galvanizing 140 g/140 g. | Foaming, cracking, color change <4 2000h |

| Solvent resistance | The butanone infiltrated gauze was wiped back and forth with a pressure of 1000g±10g. The wiping stroke was 100mm, the frequency was 100 times/min, and the contact area between the wiper and the test piece was 2cm2. | There is no significant change in the surface. MEK times 100 |

| Aging resistance | UVA-340 uses 12 hours for 1 cycle: 8h UV illumination, blackboard temperature (60±3) °C, 4h condensation, blackboard temperature (50±3) °C | There are no cracks, blistering or falling off on the surface. 3000h |

| UVB-313 uses 8 hours for 1 cycle: 4h UV illumination, blackboard temperature (60±3) °C, 4h condensation, blackboard temperature (50±3) °C | There are no cracks, blistering or falling off on the surface. 2000h | |

| The xenon lamp is aging. Source wavelength: (290-800) nm, source irradiance: 550 W/m2, black mark temperature: (55 ± 3) ° C, relative humidity: (65 ± 5)%, water spray cycle: each spray time (18 ± 0.5) )min, the waterless time between two sprays (102 ± 0.5) min | There are no cracks, blistering or falling off on the surface. 4000h | |

| Acid resistance and oil resistance | 5% hydrochloric acid, 20 oil, stand still | The film layer has no abnormal appearance changes such as discoloration, bulging, foaming, and pulverization. 720h |

| Alkali resistance | 5% sodium hydroxide, allowed to stand | The film layer has no abnormal appearance changes such as protrusion, foaming, and pulverization. 720h |

| Rub resistance | The towel was taken from butanone and rubbed back and forth 100 times with a force of 1 kg. | There is no visible color difference in the portion being wiped. |

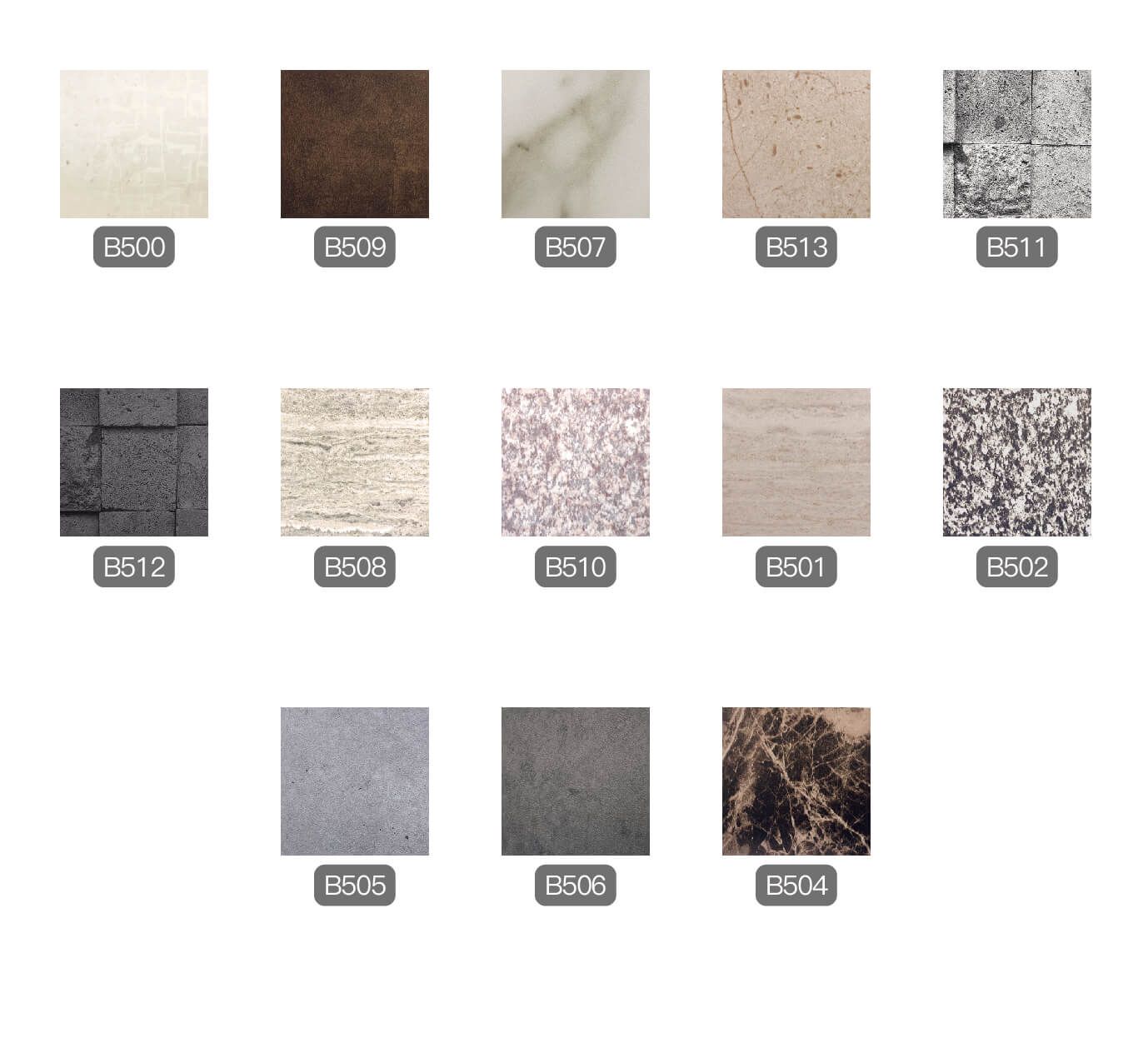

Adherence Test

The PVDF(weather resistance film) Laminated on steel has been rigorously tested after 1400 hours. The cut area of center did not peel off and lifted. Adhesion reached the 4.0 A level(better than case type attachment level). In addition to attached in high quility, that we don't worried about peeling off in processing.

- Gallery

- PVDF Outdoor Laminated Metal Application(House Exterior)

- PVDF Outdoor Laminated Metal Application(Roof)

- PVDF Outdoor Laminated Metal Application(Roof)

- PVDF Outdoor Laminated Metal Application(Corrugated Sheet)

- PVDF Outdoor Laminated Metal Application(Corrugated Sheet)

- PVDF Outdoor Laminated Metal Application(Corrugated Sheet)

- PVDF Outdoor Laminated Metal Application(Warehouse Exterior)

Laminated Metal Products | Metal Surface Processing | Lienchy Metal

Based in Taiwan since 1992, LIENCHY LAMINATED METAL CO., LTD. has been a laminated metal products manufacturer. Their main laminated metal products include, PVDF Outdoor Laminated Metal Series, pre-coated steel sheet, PPGI, PPGL, PPAL, pre-painted steel sheet, pre-finished steel sheet, anti-fingerprint stainless steel, pvc laminated metal sheet, pvc coated metal sheet, pvdf laminated metal sheet, titanium coated stainless steel sheet, pre-painted metal sheet, coil steel sheet and titanium coated stainless steel sheet, which are produced with a 350M roll-to-roll production line and 50,000 tons annual production capacity.

Lienchy Metal is capable of manufacturing ISO certified 1.6mm-thick laminated steel sheets and meet SGS, RoHS and GREENGUARD standards. We are long-term partner of EU and US home appliance brands and Japanese elevator factories, our products have also been exported to all over the world, from Taiwan, Japan, South Korea, China, ASEAN countries, the United Arab Emirates, Russia, Europe and North America.

Lienchy Metal has been offering customers high-quality laminated metal and anti-fingerprint stainless steel products, both with advanced technology and 30 years of experience, Lienchy Metal ensures each customer's demands are met.