Tedlar® PVF Outdoor Laminated Metal Series

Ultra-high performance PVF laminated metal for outdoor use

Exterior laminated metal, PVF laminated metal, Tedlar® PVF Laminated Metal

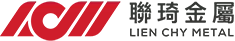

Outdoor laminated metal panels with Tedlar® PVF films are ideal for residential and industrial metal roofing, walls, and fences, providing excellent protection against wildfires, fire hazards, strong winds, acid rain, UV radiation, and other natural disasters.

This product has passed high-standard fire resistance tests and features UV resistance, acid and alkali resistance, and antibacterial properties. Not only does it enhance the aesthetic appeal of buildings, but it is also highly durable and weather-resistant, making it an optimal choice for improving building safety and longevity.

Product Description

Outdoor PVF laminated metal panels use DuPont's exclusive Tedlar® PVF film, which is firmly bonded to metal surfaces. These advanced laminated panels provide exceptional protection against sunlight, fire, strong winds, heavy rain, and extreme weather conditions, significantly extending the lifespan of buildings.

Its superior features include fire resistance, flame spread prevention, UV protection, acid and alkali resistance, and antimicrobial properties. Additionally, the product meets environmental standards by emitting minimal volatile organic compounds (VOCs).

With excellent flexibility and workability, PVF laminated metal panels can undergo bending, stamping, and other fabrication processes without cracking, making them suitable for a wide range of construction and industrial applications.

These panels are widely used in metal roofing and exterior walls for residential, industrial, and warehouse buildings, effectively reducing fire risks and preventing long-term deterioration caused by sun exposure and harsh environments. Other applications include solar panels, coastal buildings, aircraft interiors, medical facilities, and hotels.

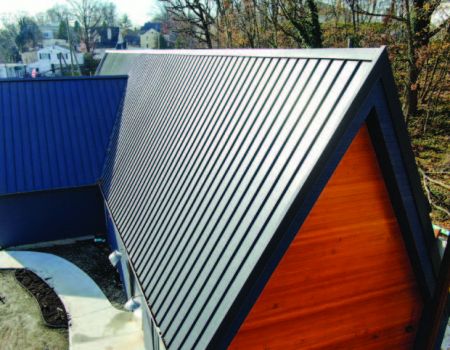

PVF Laminated Metal Structure

What is PVF Film?

PVF (Polyvinyl Fluoride), invented by Dupont in 1940 and officially trademarked as Tedlar® in 1961, has been extensively used for indoor and outdoor surface protection in aviation, automotive, solar photovoltaic, and residential building industries for over 60 years.

Compared to similar films like PVC (Polyvinyl Chloride) and PVDF (Polyvinylidene Difluoride), PVF excels in surface toughness, weather resistance, and corrosion resistance. Even in high-temperature, humid regions prone to material corrosion, PVF effectively safeguards building surfaces from extreme environmental erosion.

Product Feature

- Fire-Resistant:PVF laminated metal panels have passed strict fire safety certifications, including:

These panels effectively reduce the risk of fire spread and emit low levels of toxic gases and smoke in case of combustion, enhancing fire safety in buildings. This makes them an excellent choice for metal roofs and exterior walls in wildfire-prone areas.- Fire Resistance certified by EASA(European Union Aviation Safety Agency) & FAA(U.S. Federal Aviation Administration)

- ASTM E84 Class A (American Society for Testing and Materials)

- NFPA 286 (U.S. National Fire Protection Association standard)

- Japan Ministry of Land, Infrastructure, Transport and Tourism (NM0717, NM1553) non-combustible material certification

- Superior UV Resistance for Long-Term Protection:Tedlar® PVF film offers better UV protection compared to acrylic, PVC, and PVDF films. Even after long-term sun exposure, the panels maintain their original color, gloss, and structural integrity, making them perfect for harsh outdoor environments.

- Corrosion & Acid-Alkali Resistance:The specialized PVF film structure has chemically inert, providing outstanding resistance to chemical solvents, salt spray, acid rain, and industrial pollutants, ensuring long-term metal surface protection in coastal and high-pollution areas.

- Easy Maintenance & High Durability:The hydrophobic surface repels water stains, oil, and dust, preventing dirt accumulation. Durability tests confirm that PVF film outperforms PVDF films, requiring only water or mild cleaning agents to maintain a clean and polished appearance.

- Mold, Mildew, Bacteria Resistant: Tedlar® PVF film effectively inhibits mold and bacterial growth, passing the ASTM G21 anti-fungal test and earning UL Greenguard Gold certification. This makes it an excellent choice for medical facilities, schools, hotels, and other environments requiring strict hygiene control.

- High Strength & Excellent Workability:PVF laminated metal panels remain crack-free even after rigorous 0T bending tests. They are suitable for metal roofing, exterior walls, and fire-resistant building materials, meeting various architectural and construction needs.

- Versatile & High-Quality Aesthetic:Available in a variety of colors, including transparent, warm, cool, and neutral tones, PVF laminated metal panels offer diverse design options. Additionally, the surface texture helps reduce light pollution, contributing to an environmentally friendly architectural appearance.

Product Application

- Metal Substrate can be adhered: Stainless Steel (SUS), Galvalume (GL), Galvanized Iron/ Steel (GI), Electro-Galvanized Steel (EG), Aluminum (Al), Zinc-Aluminium-Magnesium (ZAM)

- Residential Construction Materials: Wallboards, Door panels, Ceilings, Roofs

- Industrial Facilities: Factory exterior walls, Corrugated Metal panels, Cleanroom panels, Refrigeration room panels

- Medical Facilities: Hospital and Clinic exteriors and Indoor door panels

- Public Spaces: Building exteriors and indoor spaces that require neat appearances, such as Hotels, Department stores, Restaurants

- Transportation: Carriages in cars, Buses, Trains, Plane cabins, Ship cabins interior decoration

- Photovoltaic Equipment: Solar panels

PVF Film Colors:

Tedlar® PVF film offers various colors for selection. Transparent films are also available to exhibit the original metal color.

Color Sheet

PVF Laminated Metal Test Result

| 測試項目 | 測試結果 | 測試結果 |

|---|---|---|

| Crosshatch Adhesion Test | No film was removed at cross-hatch test | Pass |

| Erichsen Adhesion Test | Less than 1 mm of excess metal exposed of the original cut after the test | Pass |

| T-bend Test | No cracking or delamination was found after 0T bend test. | Pass |

| Damp Heat Test | No squares of PVF film are removed after the test. | Pass |

| Thermal Cycling Test | No delamination of PVF film from the edges or the 0T bend. No bubbles in film. | Pass |

| Salt spray Test | Do not blister at cross, cut edge, and field. | Pass |

| Chemical Resistance Test | After saparately soak the PVF laminated metal plate in chemical solvents in sulfuric acid, hydrochloric acid, ammonia, and sodium hydroxide, no delamination or blistering on the surface. | Pass |

Some of the information and images are sourced from the DuPont official website. If you would like to learn more about PVF film testing, please visit the Tedlar ® official website or click here to view official test results. If you are interested in our products, feel free to contact Lienchy Metal, and our professional team will be happy to assist you.

- Gallery

- Train station using PVF laminated metal as corrugated metal panels as roof

- Corrugated metal panels made of PVF laminated metal

- Factory using PVF laminated metal to decorate exterior walls

- Hospital using PVF laminated metal to decorate interior walls

- Racing track using PVF laminated metal to decorate the roof

Laminated Metal Products | Metal Surface Processing | Lienchy Metal

Based in Taiwan since 1992, LIENCHY LAMINATED METAL CO., LTD. has been a laminated metal products manufacturer. Their main laminated metal products include, Tedlar® PVF Outdoor Laminated Metal Series, pre-coated steel sheet, PPGI, PPGL, PPAL, pre-painted steel sheet, pre-finished steel sheet, anti-fingerprint stainless steel, pvc laminated metal sheet, pvc coated metal sheet, pvdf laminated metal sheet, titanium coated stainless steel sheet, pre-painted metal sheet, coil steel sheet and titanium coated stainless steel sheet, which are produced with a 350M roll-to-roll production line and 50,000 tons annual production capacity.

Lienchy Metal is capable of manufacturing ISO certified 1.6mm-thick laminated steel sheets and meet SGS, RoHS and GREENGUARD standards. We are long-term partner of EU and US home appliance brands and Japanese elevator factories, our products have also been exported to all over the world, from Taiwan, Japan, South Korea, China, ASEAN countries, the United Arab Emirates, Russia, Europe and North America.

Lienchy Metal has been offering customers high-quality laminated metal and anti-fingerprint stainless steel products, both with advanced technology and 30 years of experience, Lienchy Metal ensures each customer's demands are met.